The Incredibly Superb SIRIUS Processing

Removing unnecessary burrs without damaging the surface!

- Removal of burrs you cannot even see...Removal of superfine burrs on a precision tool

For extension of lifespan of tools and blades (blade-edge polishing) burr extraction on narrow channels and surface finishing maintenance of edge quality (rounding) burr extraction and surface finishing on soft metal such as copper, zinc, tin etc.

Prevention of chipping by removing fine burr on the tip of tools

- Removing mill scale

Removal of welding burns on mirror faced stainless steel, acidized metal, laser dross, membrane, and cleaning of metal molds.

- Removing surface layer without damaging to surface

Prevention of warping, surface finishing (thin), partial removal of vapor deposited film, maintenance of the edge quality.

Processing Sample

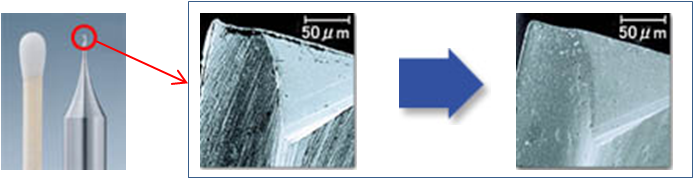

Removing of fine burr

Expansion of lifespan and prevention of initial chipping with removal of burrs after abrasion or mechanical processing of an end mill, drill, hob, gear, etc.

< [Before] [After] >

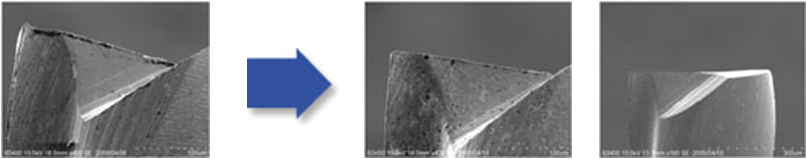

Removal of burr on cutters

Prevention of initial chipping, thus expanding the lifespan of the blade edge of a cutter.

Improvement on the durability of the coating by de-burring the surface prior to coating processes.

< [Before] [After] >

x 420x 420x 190

SIRIUS is...

It is a processing method for using SIRIUS media developed by our company for finishing without damaging the surface of metal molds and tools.

Characteristic 1. Repeatedly usable

Easy maintenance with no media recycling. Media just needs to be refilled. No need for moisture control, either.

Characteristic 2. Abrasive grain is kneaded in

Finishing is very stable. The media base and the abrasive grain are always in balance even after grinding.

Keeping a stable cutting force, usable till becoming into particles.

Characteristics 3. Small consumption

Consuming only 30g/hr. (Standard process) Major reduction in the running cost.

Characteristics of SIRIUS Processing

Processing is possible where air flow is applicable

> > Processing is possible in narrow channels, end of ditches, and corners.

Limiting the temperature on both the workpiece and the media(Air cooling)

> > Minimum heat stress to prevent physical property change of the media(Quality stabled)

Pin point processing, unlimited size and weight of the workpiece.

> > Provision of standard to large, heavy, dedicated and automated machine.

Clean dry-process with minimum generation of dust particles and collection with dust collector.

Durable and easy to apply. No need for media recycling. Continuous operation. Stable processing.

Low in running cost (Small media consumption)

Polishing, de-burring, precision cutting, rough cutting are all possible. Application pressure from low to high (0.02~0.4MPa)

The structure of SIRIUS

Media with abrasive grains kneaded into the elastic body

The workpiece and the friction > > Friction between Abrasive grain and elastic body> > cut-lip is generated with abrasive grain's cleavage (stable processing)

> > Worn elastic material and abrasive grain > > mechanically collected.